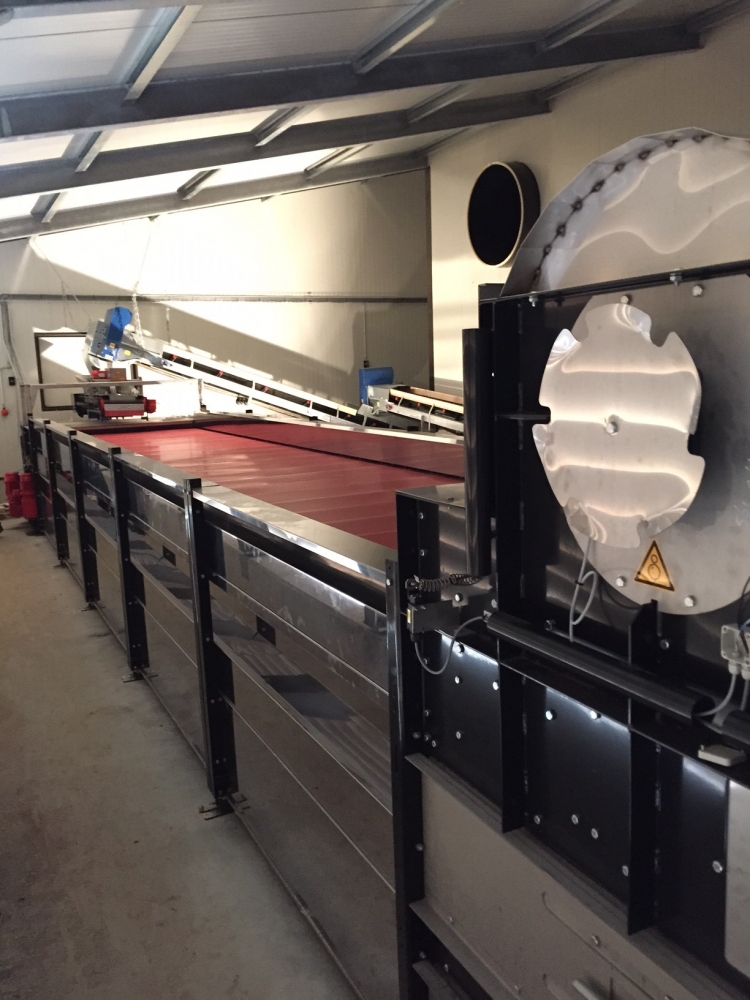

The PoulDry is a robust and reliable system

Flandr’Oeufs • Warhem • France

Victor Carton is co-owner of Flandr'Oeufs, a laying hen farm with 300,000 laying hens in Warhem, France. They control the entire production chain from laying the eggs to transporting the eggs. The Flandr'Oeufs eggs are sold under own label in stores in Northern France. In addition, they sell to wholesalers, restaurants, etc.

Given the number of laying hens, Flandr'Oeufs are obliged to dry, store and transport the manure. The dried manure must meet the standard NFU 42001.

Flandr'Oeufs uses three dryers. Two PoulDry systems together dry the manure from 140,000 hens. These dryers stand against the side wall of the poultryhouse and run once a day. Manure is stored in a separate building. This storage is much safer than storing wet manure because there is no chance of scalding because the dry matter percentage is above 80%. As a result, there is no development of flies.

The third PoulDry from VDL Agrotrech is used to dry manure from 160,000 laying hens. This is placed on the back of two poultry houses. The manure dryer runs fully automatically 3 times a day. The advantage is that they do not need a separate building for the storage of the manure.

“The PoulDry is a robust and reliable system. The system can handle wet manure well and the power consumption is lower than with other systems (manure belt aeration or tire drying tunnel). The quality of the dried manure is excellent and the moisture content is very low,” says Vincent Carton.

Central drying of poultry manure

Saudi Arabia

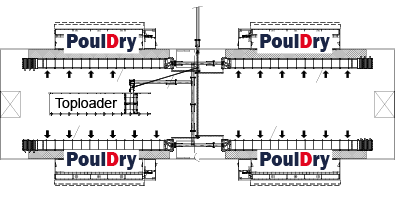

In Saudi Arabia, we supplied 4 PoulDry (VDL-6L-32M) central drying systems for processing the poultry manure from 1,200,000 laying hens (12 laying hens and 4 rearing laying hens).

Mechanism of action

The manure from the poultry houses is transported by truck to the Toploader system. From this Toploader the manure is transported to the PoulDry via conveyor belts. During transport, the manure is ground into fine pieces by a shredder. Already dried manure is added for an even better drying process.

The PoulDry drying tunnels, the top loader system, the conveyor belts and shredder are fully automatically controlled by the VDL touchscreen control panel.

Central drying

The manure is evenly distributed over the top layers of the 4 PoulDry drying tunnels via the loading unit. The moisture in the manure is evaporated with the help of warm and dry outside air. The fans, located behind the dryer, draw this air through the perforated plates, filled with 20 cm of manure. The drying capacity depends on the temperature of the air flow, the structure of the manure and the dry matter%. The speed of the dryer is controlled automatically based on the speed of drying. This is measured with dry matter sensors.

Finedust reduction and less odour nuisance

Woudenberg • The Netherlands

Bertus Verbeek runs a laying hen farm in Woudenberg, the Netherlands.

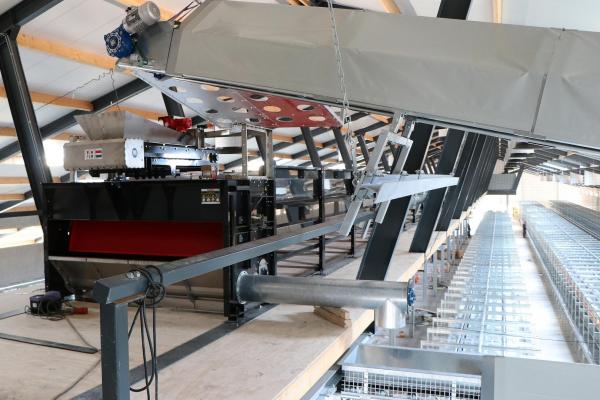

In August 2019, they commissioned a new laying hen house for approximately 55,000 free-range laying hens. They chose for the PoulDry system for manure drying. The PoulDry is 58 meters long and is placed at a height in the stable.

Almost immediately a second house was built for 50,000 laying hens and they chose again for the PoulDry to dry manure. This tunnel is 52 meters long, has also been placed at height and was commissioned in December 2019.

The two houses were built in accordance with the clean poultry house project. The Verbeek family strives to a reduction of fine dust and ammonia through the combination of manure drying, heat exchangers and ionization.

In the past, Bertus Verbeek has already worked with manure drying. “We wanted to maintain the fine dust reduction that we achieved with this. We chose for a plate dryer because it achieves a 55% fine dust reduction, compared to 35% with a tire dryer, ”says Bertus.

Bertus had a good feeling about VDL Agrotech's PoulDry system. “A fellow poultry farmer has had a PoulDry manure drying system for a number of years and is very satisfied with it. He never really had any problems. In addition, I wanted a forced tilt system”.

The location of the PoulDry manure drying system is unique in the poultry house of Verbeek. This is namely at a height of about 3.5 meters in the stable. A conscious choice of the poultry farmer.

Bertus explains: “The new poultry houses have a free-range on the side of the stable. Should we place the PoulDry system at the rear of the house, then this would have an effect on the pressure fans and we would have lost control of our house climate. You want an even airflow. The PoulDry works very well. The manure dries well and is very dry. We don't have to worry about the dryer at all and that saves us a lot of work”.

Other advantages, in addition to reducing fine dust and ammonia, are, according to Bertus Verbeek, that the storage of the manure does not stink and that there is less fly nuisance. “That is good for our environment and also pleasant for ourselves as we live next to the poultry houses,” says Bertus Verbeek.

Poultryfarm G. Ter Maaten

Country: The Netherlands

Location: Barneveld

Drying tunnel: VDL-6L-16M + VDL-4L-14M

100.000 laying hens

Poultryfarm Dijkerpeel

Country: The Netherlands

Location: Weert

Drying tunnel: VDL-4L-32M

100.000 laying hens

Poultryfarm Meevis

Country: The Netherlands

Location: Leveroy

Drying tunnel: VDL-6L-20M + VDL-4L-20M

165.000 laying hens

Poultryfarm Bojsen

Country: Denmark

Location: Horssens

Drying tunnel: VDL-4L-38M

150.000 laying hens

Poultryfarm Vandewaetere-Geldhof

Country: Belgium

Location: Ardooie

Drying tunnel: VDL-6L-30M

150.000 laying hens

Poultryfarm Keller

Country: Switzerland

Location: Freimettigen

Drying tunnel: VDL-2L-10M

12.000 laying hens